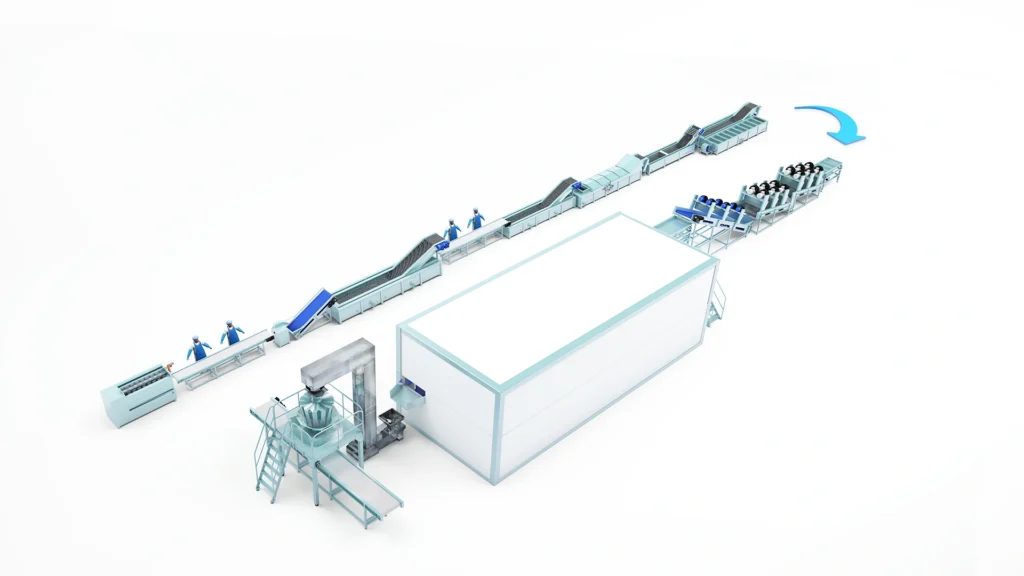

A French fry production line is a complex system involving multiple processes and equipment. From raw material processing to finished product packaging, each step requires specific equipment. The following is a detailed introduction to a French fry production line, including the main equipment and process flow.

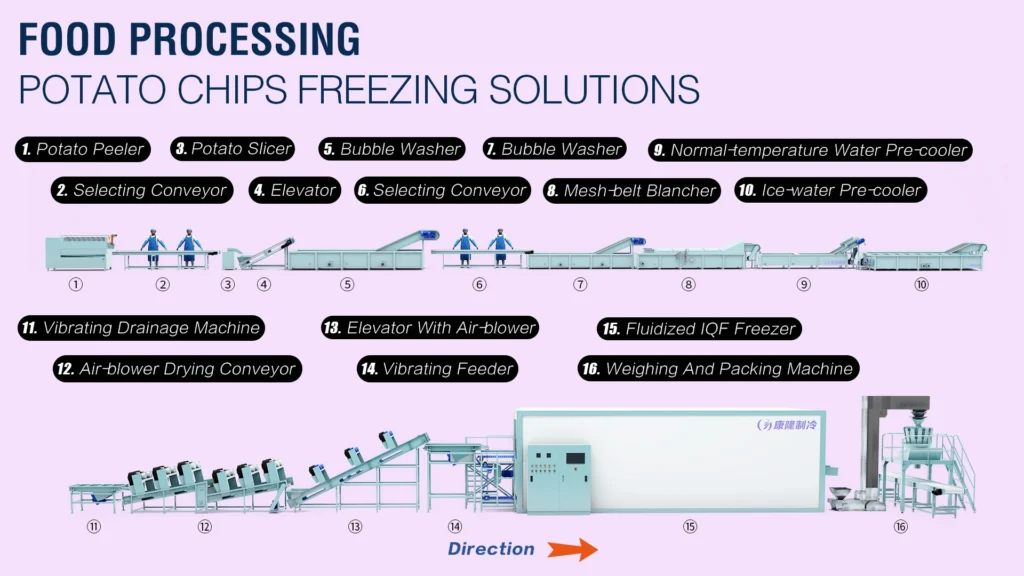

Main Equipments:

The processing line can add or reduce equipment according to different processing materials to achieve the best matching processing technology and optimal production efficiency.

Elevator:

It is used to transport raw potatoes between various equipments, reducing the labor intensity of workers and realizing continuous operation.

Potato Peeling Machine:

It adopts advanced brush principle to wash and peel potatoes, and the washing and peeling chamber adopts spiral blade propulsion to realize automatic and continuous washing and peeling.

Selecting Conveyor:

After the materials are cleaned and peeled, they are transported to the next process via a mesh belt drive. Workers manually pick out defective or incompletely peeled materials to keep the workshop floor clean.

Potato Slicer:

The potatoes are cut into uniform strips with adjustable strip size, high yield rate and smooth cut surface.

Bubble Washing Machine:

Rinse the cut potato strips to remove surface impurities and ensure that the potato strips are clean and hygienic.

Mesh-belt Blanching Machine:

It blanches the potato strips to preserve their color and kill bacteria.

Normal-temperature Water Pre-cooling Machine/Ice-water Pre-cooling Machine:

It lowers the temperature of the fries and ensures they are at room temperature before entering the freezer.

Vibrating Drainage Machine:

It removes the moisture on the surface of the potato strips.

Air-blower Drying Conveyor:

It further removes the moisture on the surface of the French fries.

Vibrating Feeder:

It vibrates to prevent the French fries from sticking together.

Fluidized Quick Freezing Machine:

The screened French fries are quickly frozen to ensure that the center temperature of the French fries quickly reaches -18°C to reduce the loss of nutrients.

Weighing And Packing Machine:

The fully automatic packaging machine completes the entire process of feeding, bag making, filling, sealing, date printing, counting, and finished product output, saving manpower and material resources.