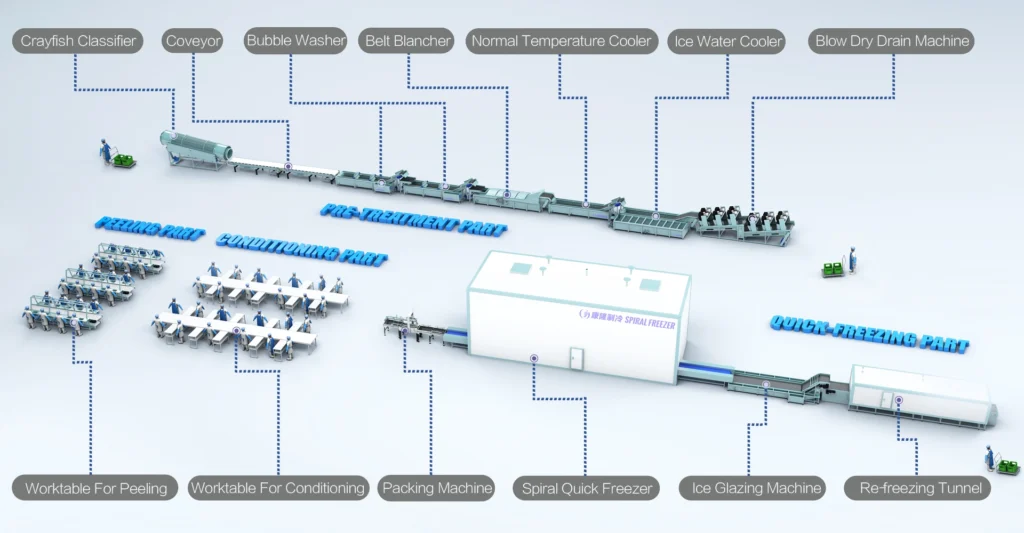

This crayfish processing solution is designed to provide crayfish processing companies with an efficient and flexible production process, ensuring optimal process flow and production efficiency at every link from raw material entry to final packaging, meeting diverse market demands and corporate production scales.

Integrated Crayfish Processing Solution

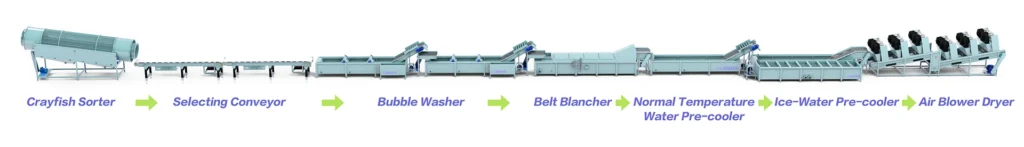

1. Pre-treatment Part

This initial and essential phase of crayfish processing comprises a set of meticulously engineered equipment. The crayfish grader precisely categorizes crayfish by size, guaranteeing consistency in subsequent procedures. The selection conveyor allows workers to manually remove defective crayfish, safeguarding the quality of input for subsequent steps. Next, the bubble washer uses vigorous bubbling to thoroughly clean the crayfish, eliminating dirt and impurities. The belt blancher then cooks the crayfish to prepare them for further processing. After cooking, the crayfish undergo preliminary cooling in the normal temperature water pre-cooler and then further cooling in the ice water pre-cooler. Finally, the air blower dryer dries the surface moisture, getting the crayfish ready for the next stage.

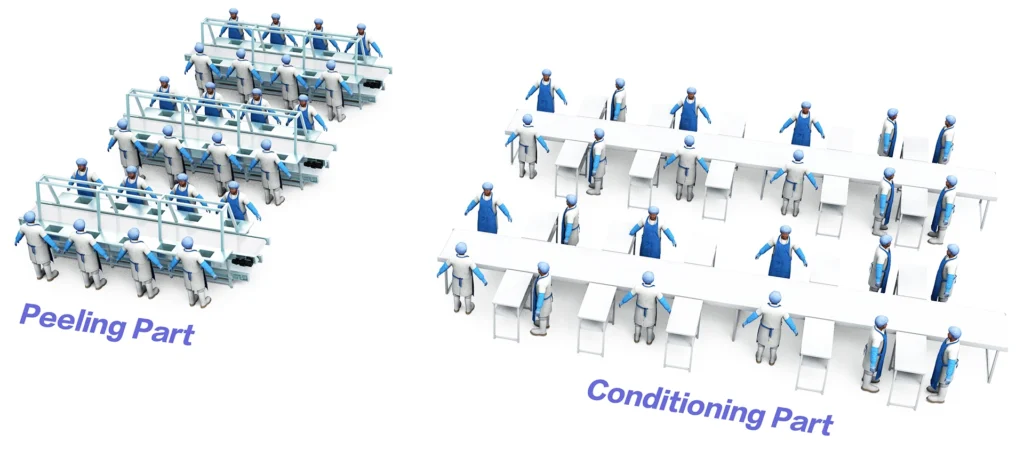

2.Manual Processing Part

This process relies primarily on manual labor and is divided into two areas: shelling and preparation. In the shelling area, workers expertly remove the shells of raw lobsters on specially constructed workbenches and extract the meat. Subsequently, in the preparation area, workers apply carefully blended seasonings to the shelled crayfish on the preparation table, imparting a unique flavor to suit the tastes of diverse consumers.

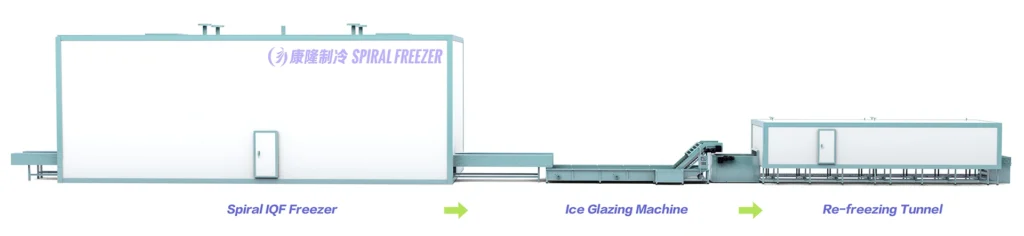

3.Quick-freezing Part

This stage is crucial for preserving the freshness and quality of crayfish. A spiral quick-freezer rapidly lowers the temperature of the crayfish, quickly freezing them to a frozen state and locking in their nutrients and flavor. An ice-coating machine then covers the frozen crayfish with a thin layer of ice, preventing oxidation and dehydration, thereby extending their shelf life. A secondary freezer further consolidates the frozen state, ensuring uniformity and stability. Finally, a weighing and packaging machine accurately weighs and packages the crayfish according to a preset weight for convenient storage, transportation, and sale.