Shrimp is a popular delicacy around the world, enjoyed in both home kitchens and high-end restaurants. Combining years of production experience and industry expertise, KLONG can custom-design a shrimp quick-freezing production line to meet all your needs.

Process:

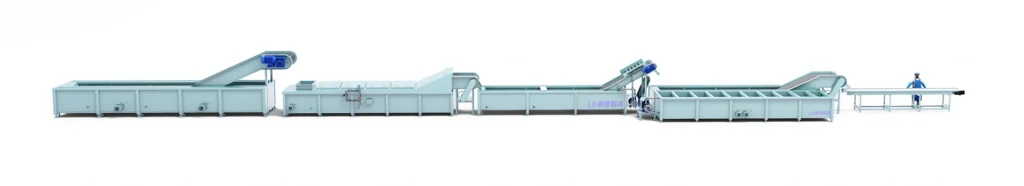

A standard cooked shrimp processing production line consists of four parts: pre-treatment processing line, shrimp grading machine, weighing and packaging machine, and spiral quick-freezing machine.

Pre-processing:

First, workers place live shrimp into a bubble washer. Afterward, the shrimp are blanched in a net-belt blanching tank. After blanching in the blanching tank, the shrimp are nearly cooked through.

Next, the shrimp are transported to two pre-cooling machines: one for ambient temperature water and one for ice water.

The cooled shrimp are then transported to a sorting conveyor, where workers sort out unacceptable shrimp.

Re-sorting and grading:

Afterwards, the shrimp are sent to the shrimp grader. Before entering the grader, the shrimp undergo two stages: transportation and cleaning. In the grading section, the gaps between the rollers vary. When shrimp are smaller than the gap, they fall off. The graded shrimp are then transported out via multiple conveyors.

Weighing and packing:

The shrimps are transported by a conveyor to a multi-head weighing and packaging machine, which weighs the cooked shrimps and evenly packs them into cartons on a conveyor belt.

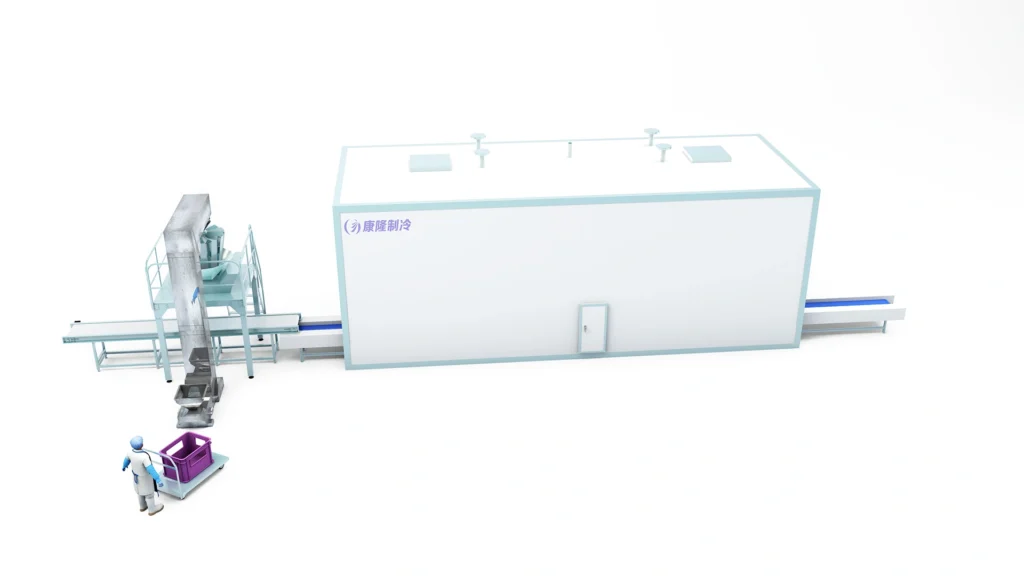

Quick Freezing:

Finally, the shrimps are sent to the spiral quick-freezing machine for quick freezing.